Activity profile - Architectural models

PRINT 3D ltd is the largest service bureau in Israel, that specialize in creating architectural models by production machines at various technologies that allow creation of physical models right from the architectural design files, illustrations and computerized models.

The uniqueness:

One of the main challenges in manufacturing models using manufacturing machines is the process of converting from an architectural plan to a production machine, a process that until now has taken weeks of manual work according to the required production process.

PRINT 3D’s solution enables the production of any physical architectural model (from any architectural file) to any production machine, without the need for adjustments or changes in the original plan. This is based on unique algorithms developed in Israel which allows the automatic transfer of a design file to the production of a physical model..

The solution enables the production of models of any size, in any color and texture, in a craftsmanship finish by experienced models and models.

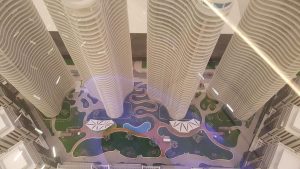

The Art of 3D Models

The release from technological limitations, allows us to focus on creating the optimal solution for the customer, according to the final product requirements, while adapting the production / machine process to the desired project. The final product includes finishing and full specification as is customary in manual models, including the development of an area that includes gardening, figures and cars, all according to the customer’s requirements.

As the largest service bureau in Israel for the manufacture of architectural models, we have printers and production machines from different technologies that are adapted to the desired product: a model, a marketing model, a design model, a white model and more. Each machine has different capabilities which are expressed in the thickness / size of the print / model requested, the type of finish desired, the color of the basic material and texture.

Advantages:

- Speed – The use of unique technology and production in a service center with a variety of options in one place, allows us to save production time: from several weeks to several days.

- Product Quality / Finishing – Lack of technological limitations allows us to focus on the final product.

- And not in the process – the finishing level is performed manually or computerized, so that the final product is a true model identical to the one-pixel program: all the elements are built by the production machines and appear in the final product.

- Unlimited copies, by any scale: An unlimited quantity of copies can be produced for each model with absolute precision for the purpose of examining different alternatives on a different scale. (From a large display sample to a small model as a souvenir / promotional means).

Modularity and Interior Design – “Sample Apartment”: The technological freedom allows the production machines to produce models that can be dismantled and the interior design: floors, levels and furniture, for example, one by one according to the elements in the program: Sample Apartment. The cutting is done by the system even if it did not appear in the initial design